T Cadmium, Bright AMSQQP416, TypeI, Class2 5 Cadmium, Olive drab AMSQQP416, Type II, Class 3 V VKEL AMSQQP416, TypeII, Class3 (Cadmium);Grade Finish Thread Specs Locking Mechanism;QQP416 AMSQQP416 Class I " minimum thickness Class II " minimum thickness Class III " minimum thickness Type I As plated Type II With chromate treatment Type III With phosphate treatment Colorless Irridescent Bronze Brown Olive Drab Yellow Forrest Green Primarily used to protect steel and cast iron against

2

Qq-p-416 type ii class 2

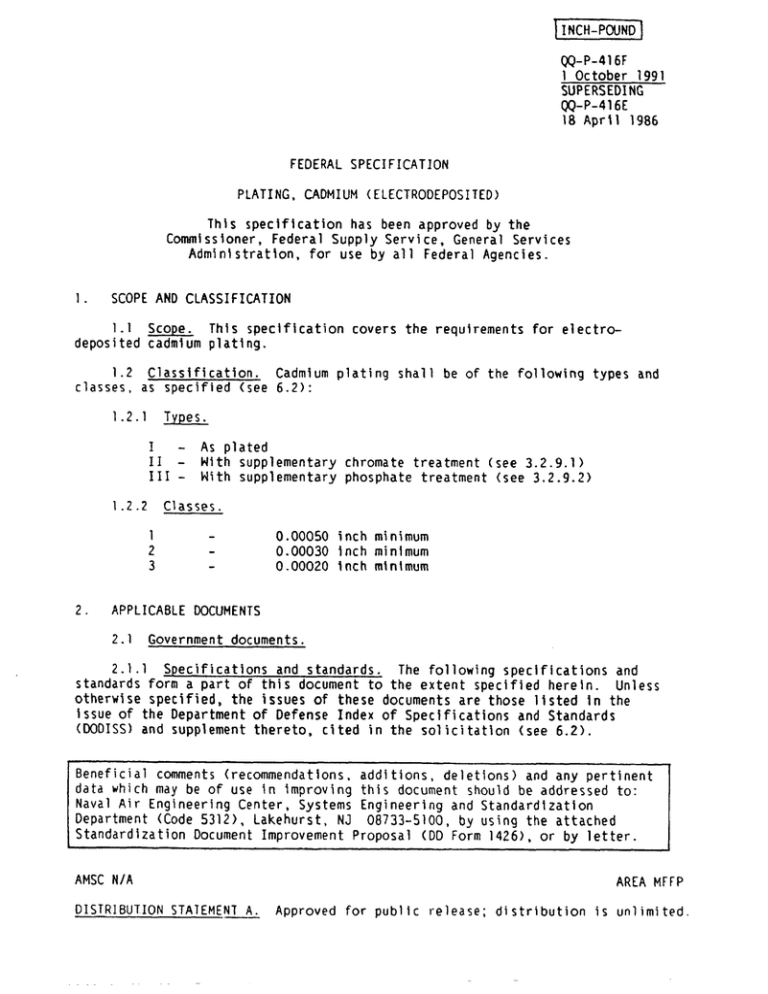

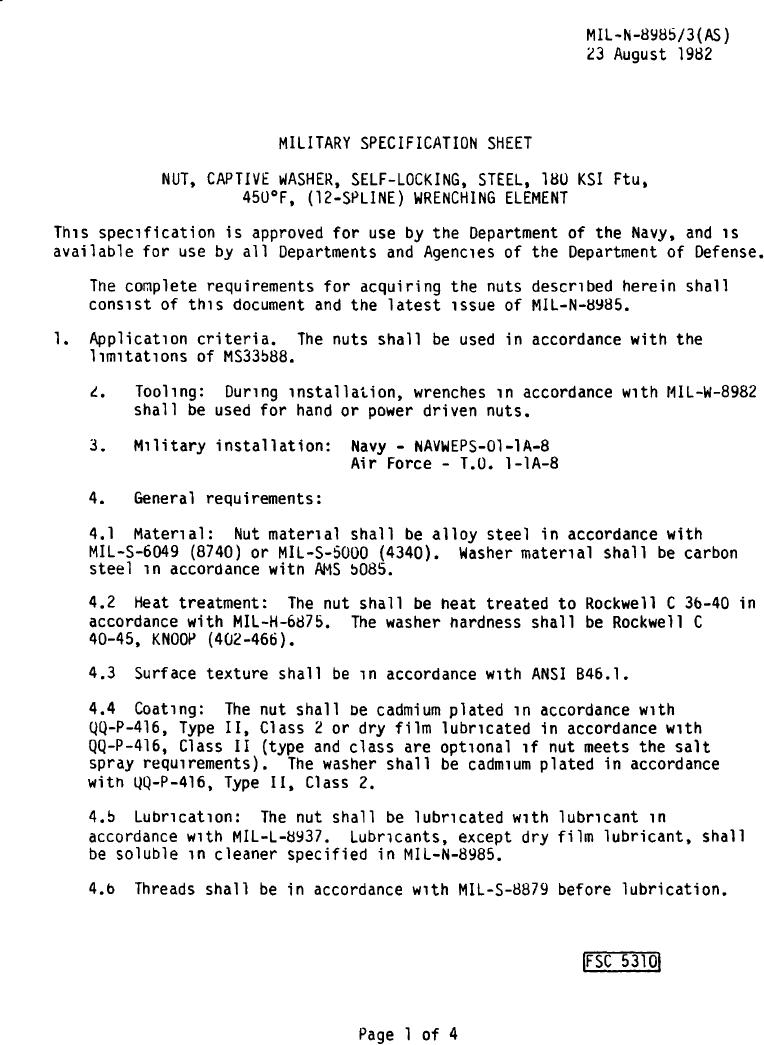

Qq-p-416 type ii class 2-Per AMSQQP416, type II, class 2 "DF" Indicates dry film lubricant per MILPRF "CW" Indicates NAFCO carbowaxQQP416F, FEDERAL SPECIFICATION PLATING, CADMIUM (ELECTRODEPOSITED) (01 OCT 1991) S/S BY SAEAMSQQP416, This specification covers the requirements for electrodeposited cadmium plating

Ansi B18 2 3 Pdf Document

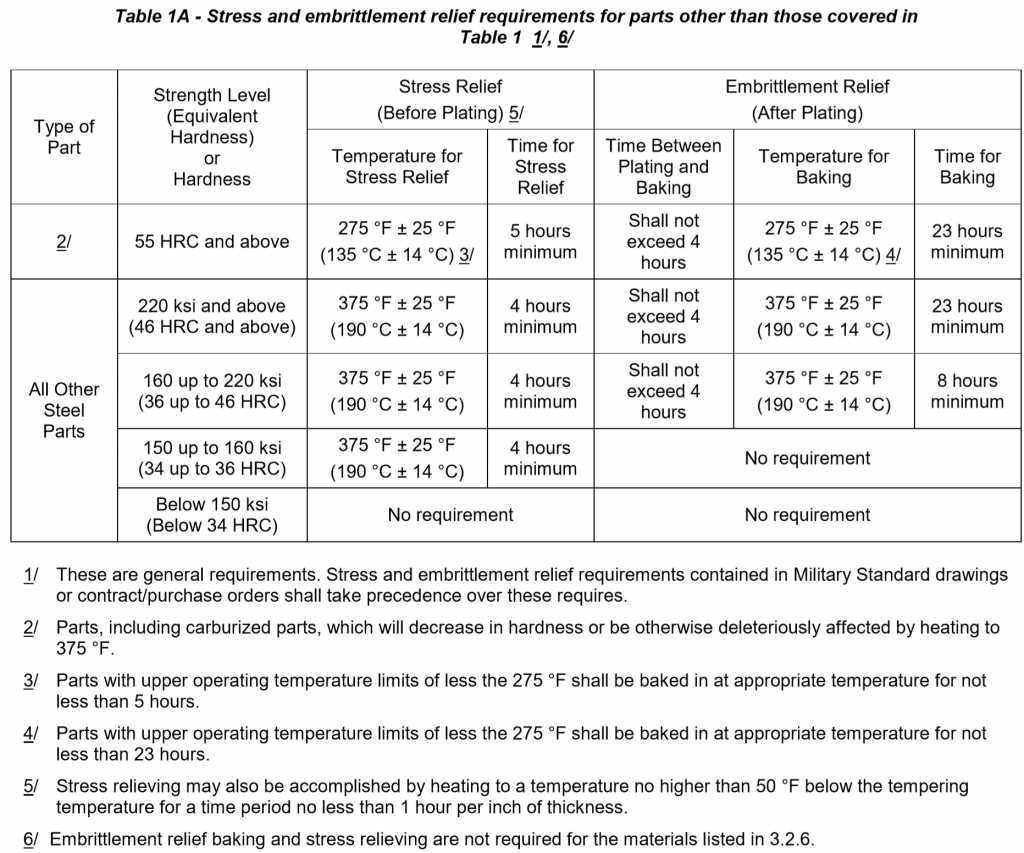

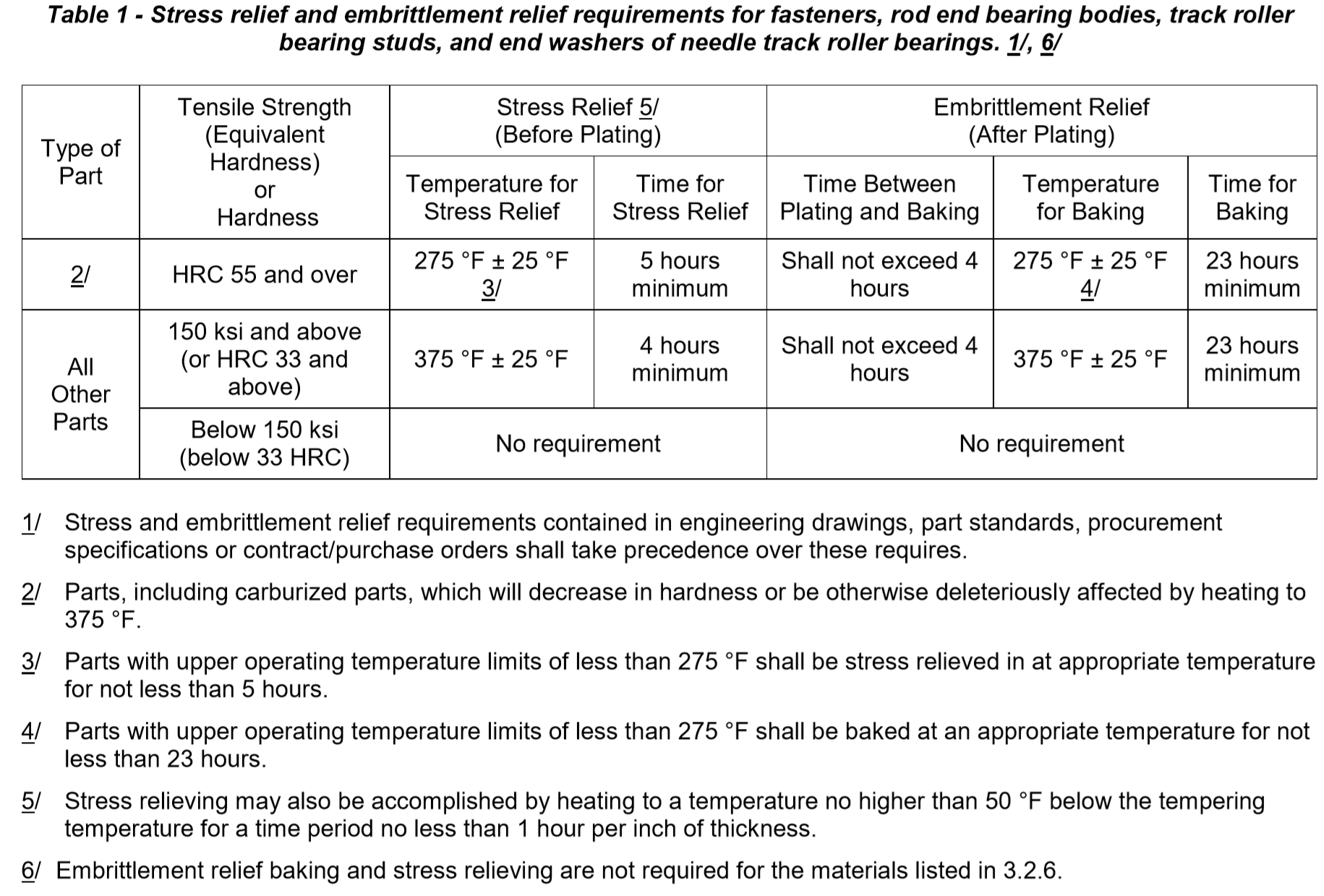

2 Dimensions are in inches and apply after finish and before application of lubricants HST75DU( )A = Solid film lube per AS5272, Type I Collar HST75( )A = Cadmium plate per AMSQQP416, Type I, Class 2 and cetyl alcohol lube Washer HST75( )DW = Solid film lube per AS5272, Type ISAE AMSQQP416, Revision F, March 21 (R) Plating, Cadmium (Electrodeposited) General Usage Processes used for cleaning and cadmium deposition on components heattreated to, or having ultimate tensile strength of 152 ksi (1048 MPa) or higher tensile strength or 34 HRC or higher, should incorporate practices and procedures to minimize hydrogen embrittlement6122 Type II handling precautlon Chromate treatments (Type II), which involve only dipping in chemical soluttons, normally require a sufficent period of drying, approximately 24 hours at 70°F to 90°F (21°C to 32°C), to render the parts suitable for handlinq without damaqe to the coating while in gelatinous forms;

SAE AMSQQP416 Plating, Cadmium (Electrodeposited) General Usage The electrodeposited cadmium platings covered by this specification are intended for use as corrosion protective coatings Processes used for cleaning and cadmium deposition on parts SAE AMSQQP416Cadmium plate per AMSQQP416, Type II, Class 2 /8/ CRES Silver plate for 800 degree Fahrenheit use per NASM to a 0002 minimum thickness on surfaces which can be touched by a (3/4 inch) diameter ball Threads shall show complete coverage, but thickness requirement on threads is waived Aluminum AlloyQQP416,Type II, Class 2 Corrosion preventative compound MILC Corrosion Inhibitors, , General 35 Black oxide coating MILC, Class 1 36 Chemical corrosion treatment of magnesium and magnesium alloys MILM3171 Contact Gulfstream Technical Operations 75 Cadmium coating Vacuum deposited MILC87, Type II, Class 2

Reference # 259N Product Description UNJF3B Nut Hex, High Tensile, Steel Steel Type C1137 OF FEDSTD66 or Carbon or Alloy Steel MILS1222 (C1137 Steel May Contain from 015 TO 035 perCENT LEAD), Cadmium Plate, SAEAMSQQ P416 Type II, Class 2 N1610 Series Product certifications may be available for thisApprovals – California Technical Plating Corp Prime Approvals Cadmium, Electrodeposited QQP416 Types I, II CalTef SP1000 Chemical Conversion Coating MILC5541 Class 1A, Class 3Cadmium Plate C2 AMSQQP416 Type II Class 2 Chem Film MILDTL5541, Type I, Class 1A (Gold) Chrome AMS 2460 Gold MILDTL454, Type II, Class 0 Nickel Plate N AMSQQN290, Class 1, Grade G Passivate P AMS 2700 Method 1, Type2, Class 1 (copper sulfate test) Phosphate PH MILDTL, Type Z, Class 2 Silver Plate S ASTM 00 Tin Plate

Approvals California Technical Plating Corp

2

Cadmium plating provides a smooth, adherent surface that is free from blisters, pits, nodules, burning, or other defects when examined visually without magnification It also provides great corrosion resistance Contact ENS Technology for more information regarding FED QQP35C cadmium plating todayCadmium Plating AMSQQP416 Ty I,II CI 1,2,3 Plating, Cadmium (Electrodeposited) Chromate Conversion Coating MILDTL5541 Chemical Conversion Coatings on Aluminum and Aluminum Alloys RPS1353 Application of Chemical Conversion Coatings on Aluminum Alloys Passivation AMS2700 Passivation of Corrosion Resistant SteelsSPECIFICATION QQ – P – 416 / AMS – QQ –P – 416 Class 1 THICKNESS" min Class 2 THICKNESS" min Class 3 THICKNESS000" min Type I DETAIL As plated, no chromate Type II DETAIL With supplementary chromate treatment (SPI provides clear, gold and olive drab chromate) Type III DETAIL With supplementary phosphate treatment (This service is not offered

Page 16 Circular Connector Backshells And Accessories

Surface Finishing Processes Electroplating

The cadmium plating shall be Type II on parts that will not subsequently be completely coated and Type III on parts that will subsequently be completely coated (see 522 and 523) 3281 Chromate Treatment The chromate treatment required for conversion to Type II shall be a treatment in or with an aqueous solution of salts, acids,QQP416E Type Class Lot hydrogen embrittlement testing if required (see 442) and sampling Basis metal to be plated Tensile strength or hardness of the basis metal Preplate stress relief to be performed by plating processor (time and temperature) Special features, geometry or processing present on parts that requires special attentionWe are using the power of our platform to aid in the mass shortage of critical supplies If your company

Qq P 416 Tech Information

Part Number Ajb 10tfa 018 Ajb Tfa Tfc Flanged Journal Bearings Sae As 2 On The Timken Company

CaD Plate Per aMs QQP416 tyPe ii Cl2 CaD Plate Per aMs QQP416 , tyPe ii Cl2 CPr CaD Plate Per aMs QQP416 tyPe ii Cl2 GreeN Par 90 CaD Plate Per aMs QQP416 , tyPe ii Cl2 Par 90 Or Bare TABLE 1 strength requirements – CCr274 (Class 1), CCr264 (Class 2), CCr244 (Class 3) Rivet Material Head ClassCres passivate per astma967, type ii silver plate per ams2410 or ams2411or cadmium plate per saeams qqp416 type ii, class 2 solid film lubricant per as5272, type i, applied to threads only (a) minimum thread "h" in short lengths minimum thread "h" where length permits shall be 2 x diameter of threadTHICKNESS PER CLASS I – ″ minimum II – ″ minimum III – ″ minimum PLATING TYPES Type I – as plated Type II – w/ supplementary Chromate treatment INDUSTRY USES Aerospace, Automotive, Electronics, Defense, Marine and more

Nas Bolts Fsaeparts Com

Cadmium Plating Macon Georgia

And it is importantAN850A Bolt, FAA 8130 available Specifications Diameter Length 031" / 016" Grip ± 016" Thread Length Material 0499" 0495" 5094" 4313" 0781" Alloy Steel Grade Finish Thread Specs Locking Mechanism 4037 or 8740 Cadium Plated, AMSQQP416, TYPE II, CLASS 2 1/2 UNF3A NoneAluminum Alloy 6061 In Accordance With SAE AMSQQ50/11 Plating code 1 cadmium with yellow chromate conversion coating in accordance with SAEAMSQQP416, Type II, Class 3 Plating code 2 electroless nickel in accordance with ASTM 33 Plating code 4 black anodize in accordance with MILA8625 Type II Class 2

Cadmium Plating For The Aerospace Industry Har Conn

Dust Cap For Plug Mil Dtl

Other Rack Gold Plating Brass;QQP416 Because of health hazards, THIS PROCESS IS NOT RECOMMENDED A coating for ferrous metals Bright silvery white Supplementary treatments for TYPE II can be golden, iridescent, amber, black, olive drab Corrosion resistance is very good, especially with TYPE II finish TYPE IIThe list below represents the processes and specifications that we perform and certify to most frequently If there is a specification or process that is not listed, we welcome your inquiries TYPE OF PROCESS SPECIFICATION Bright Nickel AMS 2403, QQN290, AMSQQN290 Brush Plating MILSTD865

5 16 Wide Area Washer Cadmium Plated Hi Line Inc

An735 30 Loop Type Bonding Metal Clamp E E Trading

Cadmium is excellent for plating stainless steels that are to be used in conjunction with aluminum to prevent galvanic corrosion TPP offers the following chromate conversions for cadmium Clear, Yellow, Black and Olive Drab Parts with a hardness greater then Rc40 shall be stress relieved prior to cleaning and plating, and should be given aMultichrome/ Microplate processes Type I and Type II cadmium plating conforms to industry standards AMSQQP416;Finish carbon steel cadmium plate per saeamsqqp416, type ii, class 2 aluminum alloy anodize per mila8625 type i, class optional cres passivate per astma967, type ii silver plate per ams2410 or ams2411or cadmium plate per saeams qqp416 type ii, class 2 solid film lubricant per as5272, type i, applied to threads only

Page 367 Is Rayfast Catalogue Issue 9 17

Sae Ams Qq P 416e 16 Sae Ams Qq P 416e 16 Plating Cadmium Electrodeposited

Nickel alloys Bright gold;Finish Cadmium Plated per QQP416, Type II, Class 2 CA10( )C — — Material Alloy Steel Heat Treat Per MILH6875 Fininsh Cadmium Plated per QQP416, Type II Class 2 — — CA( )HS Material 86 CRES Heat Treat Per MILH6875 Finish Passivated per QQP35 CAT( ) — —Cadmium Plate per QQP416, Type II, Class 2 Cadmium Plated per QQP416, Type II, Class 2 2530 lb View CAD Contact Howmet Fastening Systems COVID19 Response Can Your Company Help Provide Critical Supplies?

Te Com

Cadmium Plating New Method Plating Company Inc

View Lab Report cataloganmshardware from AMT 1701 at Florida State College at Jacksonville AN3 thru AN AIRFRAME BOLTS Steel Cadmium plated per QQP416, Type II, ClassFlat Head Machine Screw with Plate per QQP416, Type II 100 Degree Check up to five results to perform an action larger image Results Per Page 25 50 100 0 Results 1 25 of 94Surface Treatment Document And Classification QqP416, Type Ii, Class 2 Fed Spec Single Treatment Response Overall Related Items Military Standard MS253P570 Cad Plated Stainless Steel Rod, Straight, Headless

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Quantity Of 50 Per Package Sxs10k166cy Sherex Sx Series Rivetnut Insert Unified 10 32 Unf 3b Thread Size 116 166 Grip 2 94 4 21mm Grip Round Body Countersunk Head Keyed Low Carbon Steel Cadmium Plate Per Sae Ams Qq P 416

Qqp416, type ii, class 2113 cadmium (yellow chromate)000 min qqp416, type ii, class 3181 zinc min no under plate necessary qqz325, type iMK1000 (*)CW Cadmium plate per AMSQQP416, Type II, Class 2, plus polyethylene glycol 8000 PERFORMANCE NASM TEMPERATURE 450°F VARIATIONS Add "BC" for bottom countersunk rivet holes Example MKBC Unit of Measure Imperial Metric BothRKEL W W VKEL To meet AS requirements Y ZincCobalt, Dark Olive drab ASTMB840 Z

Cadmium Plating Sheffield Platers

Nasm Datasheet Pdf Datasheet4u Com

Reference # 2F52N Product Description UNJF3B Nut Hex, High Tensile, Steel Steel Type C1137 OF FEDSTD66 or Carbon or Alloy Steel MILS1222 (C1137 Steel May Contain from 015 TO 035 perCENT LEAD), Cadmium Plate, SAEAMSQQ P416 Type II, Class 2 N1610 Series Product certifications may be available for this productQQP416 Type 1, 2;THREAD AS79 MATERIAL Carbon steel, heat treated FINISH MF5000(*) Cadmium plated per fed spec AMSQQP416, Type II, Class 2 Kaylube

Cadmium Plating Texas Precision Plating

Ms Unc Unf Pan Head Las Aerospace Ltd

Cadmium Plate w/Chromate Dip, AMSQQP416, Class 2, Type II Cadmium plating is used on carbon steel to increase the corrosion resistance of the product The process of cadmium plating spiral retaining rings is costly and subjects the ring to the possibility of hydrogen embrittlementCadmium Plated, AMSQQP416, TYPE II, CLASS 2 Thread Specs 1032 UNF3A Locking Mechanism None The prints & data found here within are not to be used for the manufacturer, procurement, or use of this product They are for educational proposes only DRAWING(S) PDF Drawing of AN36A SeriesG AMSQQP416 Cadmium Plating Types g Type I – as plated g Type II – with supplementary Chromate Treatment g Type III – with supplementary Phosphate Treatment Thickness per Class Class 1 – " min thickness Class 2 – " min thickness Class

Buerklin Com

Drilled Jam Nut Wicks Aircraft Supply Company

Cadmium Type I, II Class 1, 2, 3 AMSQQP416 *QQP416 Electrodeposited Cleaning Surface Treatments MILS5002 TTC490 Chemical/Abrasive High Humidity Testing AMSSTD753 Method 101 Water Immersion AMSSTD753 Method 100 Copper Sulfate AMSSTD753 Method 102 Passivation AMS2700 *AMSQQP35 *QQP35 ASTM A 967 ASTM A 380Finish Cage and Housing Passivated per QQP35 Screw Dry Film Lubed C Ca Same as above except Cage Finish Cadmium Plated per QQP416, Type II, Class 2 C010C 1Lug0 Radial Float LiveSert* Material Part No Approx Weight lbs/ea Part No Approx Weight lbs/ea Cage 300 Series CRES Screw 86 CRES2 FSC 5310 ITEM NAME Washer, Lock, FlatInternal Tooth ITEM NAME CODE (INC) SPECIFICATION MS MATERIAL Carbon SteelComposition 1, FFW100 FINISH Cadmium QQP416 Type II, Class 2 Note LockWashers considered for use in Electrical Components

2

Processes Omni Pasivation Process Ams 2700 Ams Qq P 35 Astm A 967 Astm 380 Supplementary Pdf Document

Also known as SAE AMSQQP 416 SAE MOBILUS Subscribers can view annotate, and download all of SAE's content Learn More »4037 or 8740 Cadium Plated, AMSQQP416, TYPE II, CLASS 2 5/1624 UNF3A Drilled Shank I have a question and someone can help clarifying the definition of a lot in accordance with AMSQQP416 Para 4421 as follow "Lot shall consist of plated articles of the same basis metal composition, class, and type plated and treated under the same conditions and submitted for inspection at one time"

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Parker Com

Nickel Plating We process sulfamate nickel plating class 1 and class 2 with dull or satin finishes that are applied for corrosion protection The nickel plating process can be applied as anQQP416F 3292 Phosphate treatment Unless otherwise specified in the contract or order (see 62), the phosphate treatment required for conversion to Type III shall produce a tightly adherent film conforming to Type I of TTC490 33 Detail requirements 331 Thickness of plating Unless otherwise specified (see 62), theCadmium Plated, AMSQQP416, TYPE II, CLASS 2 Thread Specs 1/428 UNF3A Locking Mechanism None The prints & data found here within are not to be used for the manufacturer, procurement, or use of this product They are for educational proposes only DRAWING(S) PDF Drawing of AN46A Series

Ns Yb05c Controller Datasheet Pdf Display Controller Equivalent Catalog

2

Enhanced durability Gold plating deposits a thin layer of gold onto the surface of another metal, by chemical or electrochemical plating With only a thin layer of gold required, it can be cost

Aerospace Material Specification Plating Cadmium Electrodeposited Pdf Corrosion Heat Treating

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Everyspec Com

Speedcomfly Com

Nasm Nut Datasheet Pdf Nut Equivalent Catalog

Cadmium Plating Alternatives

2

Ams Qq P 416 Cadmium Plating Coating Services Incertec

Mil Spec Washers 10 Ms Military Split Lock Washer Fastenerexpert Us

Evaluation Of Alternatives To Electrodeposited Cadmium For Alcoa

Ansi B18 2 3 Pdf Document

Page 316 Fiber Optic Connectors Termini And Cables Glenair

2

Integral Keylocking Insert 4140 Alloy Steel Request For Quote Acme Industrial Co

Isgroup International Com

2

Flamecorp Com

Seastrom Mfg Com

Floating Clip Nut Wicks Aircraft Supply Company

Cadmium Plating Sheffield Platers

2

Passivation Of Stainless Steel Astm 67 Ams 2700 Qq P 35

2

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Cadmium Plating Service Toronto H E Plating Ltd Electroplaters In Toronto Ontario

Tye03 Hole Datasheet Pdf Clearance Hole Equivalent Catalog

Flathead Threaded Insert Open End Keyless Metric On Pennengineering

Cadmium Plating Sheffield Platers

Mil Spec Disc Springs Mil Spec Springs

Alliedelec Com

Pccfasteners Com

2

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Ms356 Series Pan Head Phillips Machine Screw Repl An515r Series Sku Scrw Ms356 An515r

Aerospace Material Specification Plating Cadmium Electrodeposited Pdf Corrosion Heat Treating

2

2

6 Ms Military Split Lock Washer Cad Ii Per Qq P 416 Type 2 Class Bolt Demon

119 23 16

D7118

Cadmium Plating Sheffield Platers

Monadnock Floating Clip Nut Sku Mndnck Clpnut

Oem Spec Description Abex Ps102 Passivate Aero Union Corporation Aups 7 04 Topcoat Aero Union Corporation Aups Topcoat Aerofit Inc Pdf Free Download

Aerospace Material Specification Plating Cadmium Electrodeposited Pdfcoffee Com

Qq P 416 Tech Information

Processes Omni Pasivation Process Ams 2700 Ams Qq P 35 Astm A 967 Astm 380 Supplementary Pdf Document

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Tension Bolts Nas6303 Pilotshop

2

Ccr274ss A Cres Solid Film Lube Passivate Ccr274cs P E R Per Per Per Ms604r Ams 5731 Astm A 493 Mil L Qq P 35 L F Pdf Free Download

Cadmium Nadcap Co Operative Plating

Locking Washer Wicks Aircraft Supply Company

Ams Qq P 416

Qq P 416 Cadmium Plating Keystone Finishing

Te Com

Performance Of Three Alternating Coatings

2

1 2 Flat Carbon Steel Aircraft Washer Cadmium Plated Hi Line Inc

Pccfasteners Com

2

Approvals California Technical Plating Corp

Amazon Com 4 Ms Military Split Lock Washer Cad Ii Per Qq P 416 Type 2 Class 2 Pack Qty 5 000 Ms 40cd By Shorpioen Industrial Scientific

Plating Specifications General Information Pdf Free Download

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Nut Captive Washer Self Locking Steel 180 Ksi Ftu 450f 12 Spline Wrenching Element

2

Sae Ams Qq P 416 R Plating Cadmium Electrodeposited

Countersunk Head Threaded Insert Closed End Keyless Unified On Pennengineering

Thin Dense Chrome Plating Cadmium Plating Ams Qq C 3 Ams Qq P 416

0 件のコメント:

コメントを投稿